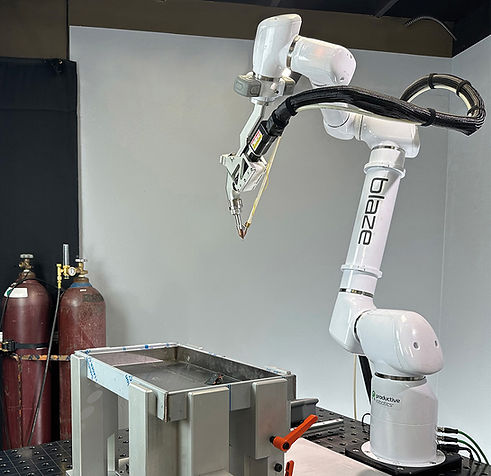

Blaze Laser Cell

Automated laser welding that doesn't require a laser darkroom

-

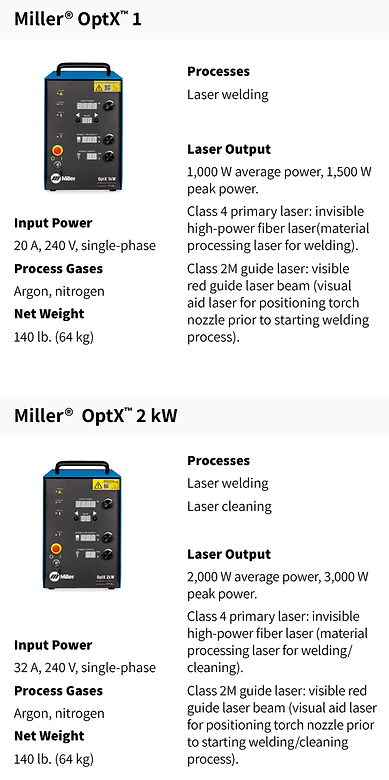

Welder options: Miller® OptX 1 kW or 2 kW Laser

-

Blaze™ 7-axis, zero programming cobot

-

Fully enclosed standalone solution

-

Live video monitoring - visors or goggles not required

-

Active fume extraction with easy ducting out

-

Large format work area with LED lighting

-

Warranty: 3 years on Blaze Laser Cell, Blaze Cobot and Miller® Welders

-

Software: Zero programming, unlimited weld capability

-

Table: 4 ft x 8 ft

Proprietary Blaze Vision Live Video so that operators can monitor the welding in progress in real time from two views without the need for welding visors, goggles or welding screens.

Turnkey and simple for any size shop to set up out of the box – without the need for third-party integrators.

Unlimited weld complexity and control with full customization of welding parameters, weld recipes, weld types and automation of Miller weld presets.

Blaze + Miller OptX

Inside the Laser Weld Cell: the ultimate cobot plus the ultimate laser

-

Designed and built in the USA with direct factory support

-

7-axis positioning allows more welds without refixturing

-

Welds dissimilar materials of different thicknesses

-

Aesthetic high strength joints with minimal or no wire

-

Software: Zero programming, unlimited weld capability

-

Reach: 61" or 85" including laser

Automate repetitive welds

New welders can be trained within hours and experienced welders realize an immediate increase to productivity

Double productivity—at a minimum

Choose presets or user defined modes for simple material preparation and minimal post-finishing, plus wobble welding and wire feed options

Strengthen teams & empower welders

High-speed welding with low heat input for minimal part distortion, improved visual appearance and increased overall part quality

Blaze Laser specifications

Teaching: Zero programming

Motion: 7-Axis torch positioning

Weld Library: Unlimited

Repeatability: +/- 0.1 mm (.004”)

IP Class: IP 61

Cobot Safety: Speed & force limited

Laser versus

traditional welding

Laser welding utilizes a highly concentrated laser beam to create precise, deep welds with minimal heat-affected zones, making it ideal for thin materials and intricate designs.

Consider laser welding for high-speed processing, reduced distortion, high precision, efficiency, and reduced post-processing requirements.

Laser weld thick, thin & reflective materials

Blaze Laser with Miller® OptX® opens the door to welding a wider range of materials and thicknesses with minimal distortion, deformation, undercut or burn-through.

Stainless Steel

Galvanized Steel

Mild Steel

Aluminum 3 & 5 Series

Aluminum 6 Series

Nickel Alloys

Titanium

Copper

Weld Seam Width

Pre & Post-Weld Cleaning

up to 0.315"

up to 0.315"

up to 0.315"

up to 0.315"

up to 0.200"

up to 0.275"

up to 0.275"

up to 0.120"

up to 5 mm

up to 15 mm

Single system welding & cleaning

Blaze with MIller® OptX® 2kW can switch from welding to cleaning in just seconds. The specially designed welding and cleaning nozzle tips provide for any joint configuration. Using a single system for multiple fabrication processes is a highly efficient productivity booster.

PRE-Weld

cleaning automation

Blaze with Miller® OptX® 2 kW provides pre-weld cleaning for fast and effective removal of contaminants such as oxides, rust, paint, oil, or grease from the surface without the use of chemicals or abrasives that can compromise weld integrity. Pulsed cleaning power up to 2500 W peak power evaporates undesired surface elements.

Photo credit: IPG Photonics®

POST-Weld

cleaning automation

Blaze with Miller® OptX® 2 kW also provides post-weld cleaning to remove soot, debris, or any sign of localized heating. Create visually appealing welds while eliminating need for post-grinding and dramatically reducing time, cost and scrap. Up to 15 mm of adjustable cleaning width in one pass.

Photo credit: IPG Photonics®

Customer spotlight video: Laser welding replaces 1,000 spot welds to speed up commercial oven production

Included with all Blaze collaborative robots

Sealed control computer

Fully integrated electronics. Sealed cabinet protects all electronics from metal dust and gunk.

Specifications

IP Rating: IP61

Communications Hardware: Ethernet 100MB

Protocols: Ethernet IP, TCP/IP, Modbus

Power: 100-240 VAC 50-60 HZ

Zero programming tablet

Using visual ‘tiles’ and a drag & drop interface, Blaze’s control tablet is incredibly intuitive to use.

Specifications

IP Rating: IP41

Connection: USB

Dimensions: 253 mm x 125 mm x 37 mm (10” x 5” x 1.5”)

Cable: 5 meters (16 ft)

Updates, info & resources

Access a comprehensive library of documentation, including product manuals, user guides, video tutorials and software downloads.

Automate with confidence. It's easy to get started.

Request a quote

Questions or unique requirements? We'll respond quickly and are always ready to talk, offer ideas and discuss solutions. Many shops find it helpful to see our cobot capabilities and unmatched ease of operation in an online demo.

Challenge us! Our cobots can easily automate almost any task—and anyone can use them.